Discover the brands and technologies from our business units Henkel Adhesive Technologies and Henkel Consumer Brands.

3 July 2020 Düsseldorf / Germany

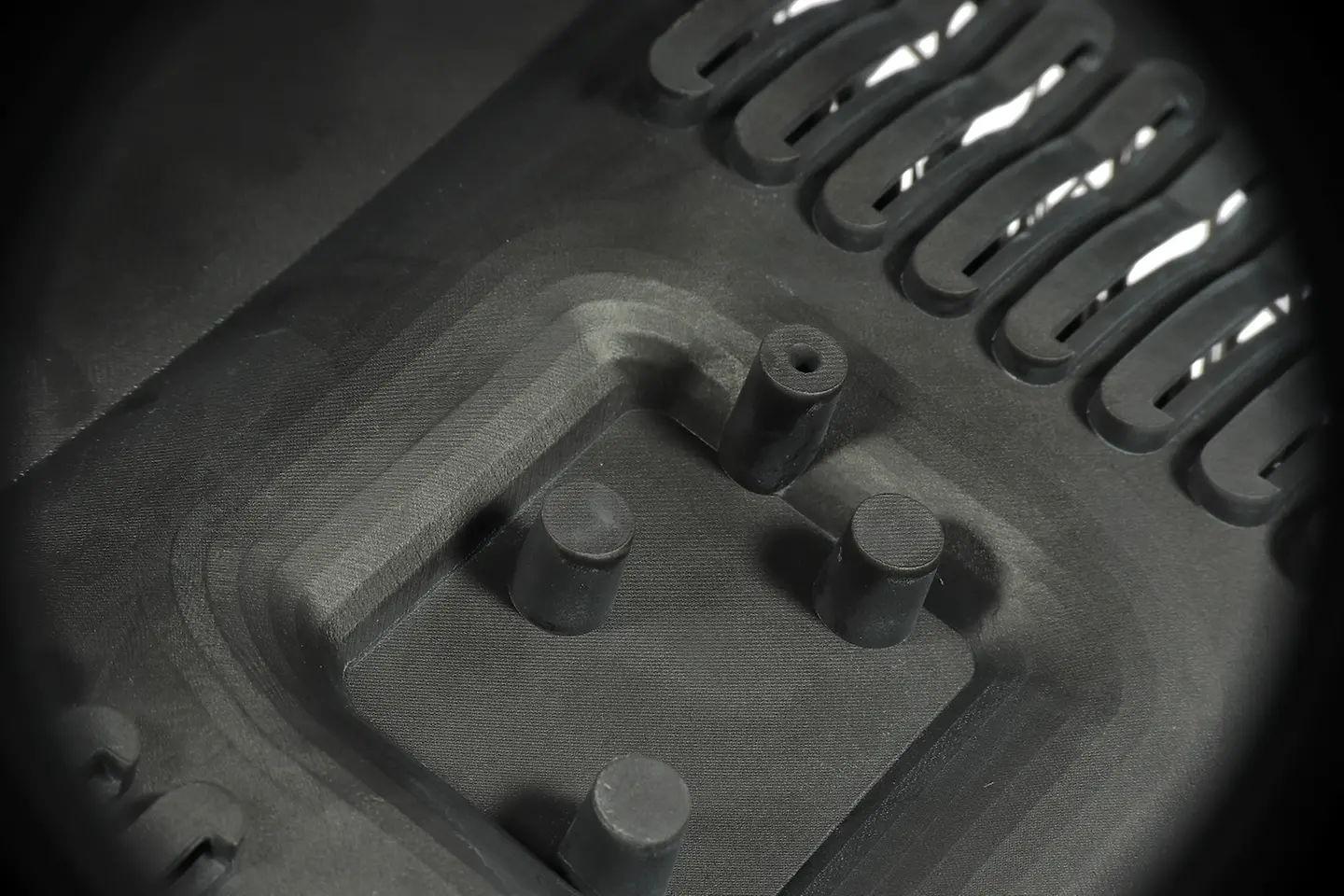

Asiga leverages Henkel’s Open Materials Platform to focus on 3D printed production parts

Asiga, an industry leading manufacturer of 3D printing equipment, has joined Henkel’s Open Materials Platform to provide the additive manufacturing industry with production-grade 3D printed parts that are both accurate and functional. Henkel offers a broad portfolio of materials for the 3D printing industry. The company develops and provides a wide range of photo-curing resins that enable ultra-fast manufacturing of production parts with many different properties, from high-impact to highly flexible, in addition to those with high heat resistance and others for specialty applications. Working together, the two companies are leveraging their deep experience in chemistry and 3D printing technologies to drive the next level in additive manufacturing production.

Asiga was an early innovator in desktop stereolithography, launching the world's first LED based DLP 3D printer in 2011. Today the company continues to focus on a range of process monitoring technologies which control part accuracy and production stability across many industries including medical and general manufacturing. Asiga's product line consists of powerful desktop 3D printers with their MAX series through to their large format floor standing PRO 4K.

Asiga's commitment to provide our customers with a stable and consistent additive manufacturing solution for end-use functional parts is now delivered with optimized compatibility with Henkel materials.” says Asiga’s Director of Global Operations, Graham Turner. “To supplement traditional manufacturing processes that require the kind of tough, functional and high temperature materials that are Henkel’s bread and butter. We’re excited to tap into the Loctite portfolio and build solutions that exceed our customer´s expectations.”

Asiga’s robust SPS™ technology and Open Material System provides a repeatable, productive and accurate 3D printing platform for Henkel’s novel additive manufacturing materials. Asiga has validated several materials for use on the MAX and PRO 4K series printers, including:

- Loctite 3D 3843 HDT60

- Loctite 3D 3172 HDT50

- Loctite 3D 3860 HDT180

- Loctite 3D 3840

- Loctite 3D 3820 Ultra Clear

- Loctite 3D 5010 A60 SI

- Loctite 3D 5015 A80 SI

“Asiga offers an innovative open platform that is cohesive with many of our materials,” says Sam Bail, Head of OEM Partnership, 3D Printing at Henkel. “We also share a common vision of unlocking the promise of additive manufacturing at scale. The industrial sector is ripe for development, and with our combined solution, we are poised to help customers benefit from many of 3D printing’s biggest advantages, including design innovation, customization, speed, and scalability, among others.”

Companies who are interested in learning more about how the collaboration between Henkel and Asiga can help drive their digital manufacturing initiatives are encouraged to visit www.Asiga.com or one of its authorized resellers, including German-based Litholabs, or US-based Proto Products.

About Asiga

In 2011 Asiga launched the world's first LED based DLP 3D printer and started the affordable desktop stereolithography revolution which changed digital manufacturing forever. Asiga gained international recognition for the innovations contained within their precise and repeatable 3D printers. These technologies continue to lead their respective categories to this day. Asiga designs and manufactures all products at their headquarters in Sydney, Australia. For more information and a list of Asiga resellers, please visit asiga.com.